Igus expanded its xiros guide roller line to include a dissipative variant made of stainless steel a kind of rotating lightning conductor that ensures a controlled electrostatic discharge. Roller of Pulley Profile Another way to track a belt involves the use of either a radial or trapezoidal profile on a roller or pulley.

Crowning Benefits Paper Film Foil Converter

If the arc of contact of snub rollers sup - port and guide rollers is small the dia-meters of these rollers may equal 12 d.

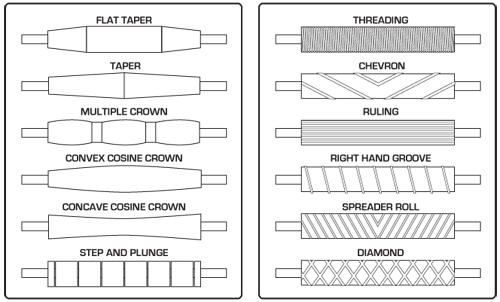

. As a general rule only as many pulleys and rollers should be installed as are necessary to carry and guide the belt. Such arrangements are used when wide spans or high moment loads need to be supported. To increase the life of cylindrical roller bearings the profile or the crowning of the roller plays an important role.

The influences of the rollers profile on stiffness stress distribution of roller linear guide are analyzed using finite element simulation. Crowned Races in contradistinction to conical races would function with less scuffing in rollerrace contact areas. We make corrugated sidewalls.

Including styles such as Cylindrical Convex Crown Straight Taper with Center Flat Straight Taper Concave Crown and more. It is compatible with most of the belt types. Roller from product debris.

Slotted mounts are suitable for less heavily loaded rollers eg. The ends of the roll face are the smallest diameter while. For pivotable carrying rollers.

If you need this in bulk we have it available. Snub rollers are used when. The Roller Company provides a range of precision machined industrial roller crowning and grinding services to ensure you get the most out of your precision machined industrial rollers.

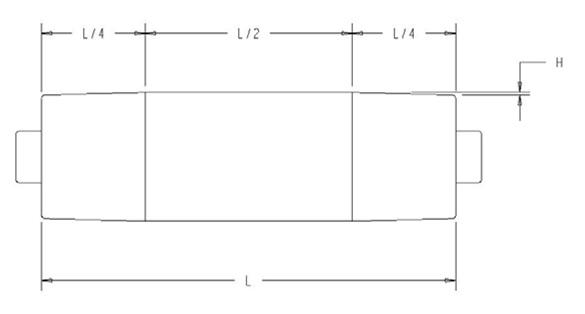

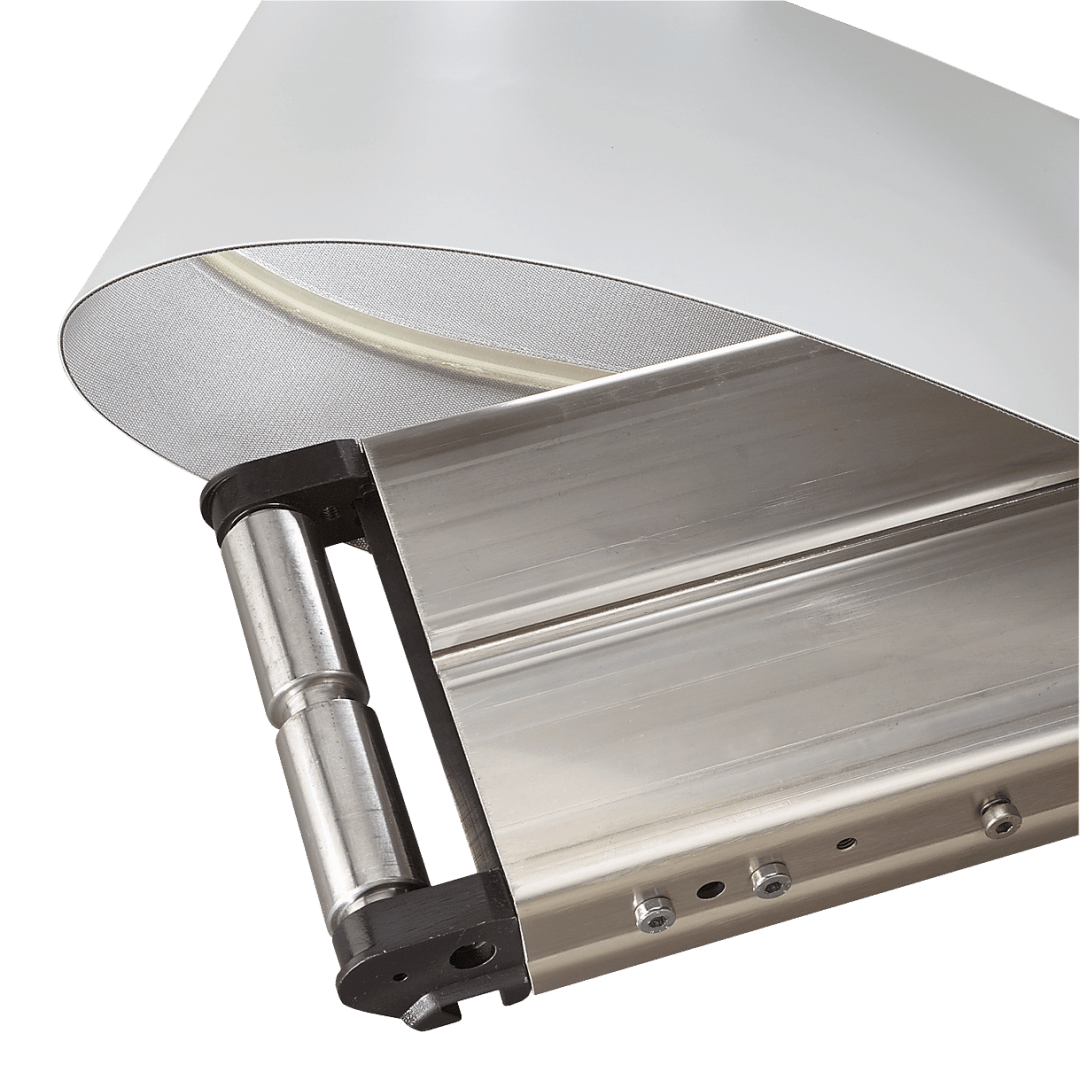

The different arrangements can counteract each other. The shape of a crown is nominally the shape of a beam deflected under a uniformly distributed load as shown in Figure 3. A crowned roller is a drive drum with a cylindrical center section with a tapered section on each end.

Below we have listed some pros and cons of the crowned pulley. Each pulley and roller can be the cause for belt running problems as well as for accumulation of debris. The tracking methods work by using the tapered ends in order to steer the belt back to the center.

A flat profile of the rolling. These rollers are available in stock sizes 608 6000 and 6001 with a stainless steel tube length of 100 to 1000 millimeters. The Computer-Aided Design CAD files and all associated content posted to this website are created uploaded managed and owned by third-party users.

A crowned spreader roll has an arced surface across its face with the arc sweeping from the ends out toward the center of the roll face. MadeWell Crown Rollers can be used in conjunction with DualVee Guide Wheels for applications requiring pairs of linear guide systems operating in parallel. In a crossed-roller bearing the races are conical surfaces at angles of 45 to the axis of rotation.

Do not crown a drive roller or pulley when there are other tracking devices on the conveyor. Corrugated sidewalls splicing accessories. Conveyor design can aid greatly in minimizing the issues associated with belt tracking.

Millions of Customers Choose Zoro. The accuracy and efficiency of a machine toll are determined by the stiffness and friction torque of roller guide. Designed to run on flat surfaces or in C channel track the uses are limited only by your imagination.

Crowned pulley comes with tapered ends and cylindrical middle section. The conveyor belts arc of contact on the drive drums is to be increased. Fast Free Shipping on Orders Over 50.

It can also be used on nose bar transfers. It is fabric-reinforced on a base and can be made in various heights. The distance between the top and return side must be small for design or construction reasons.

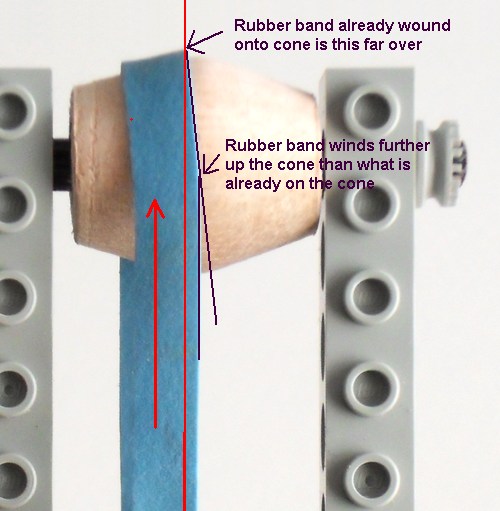

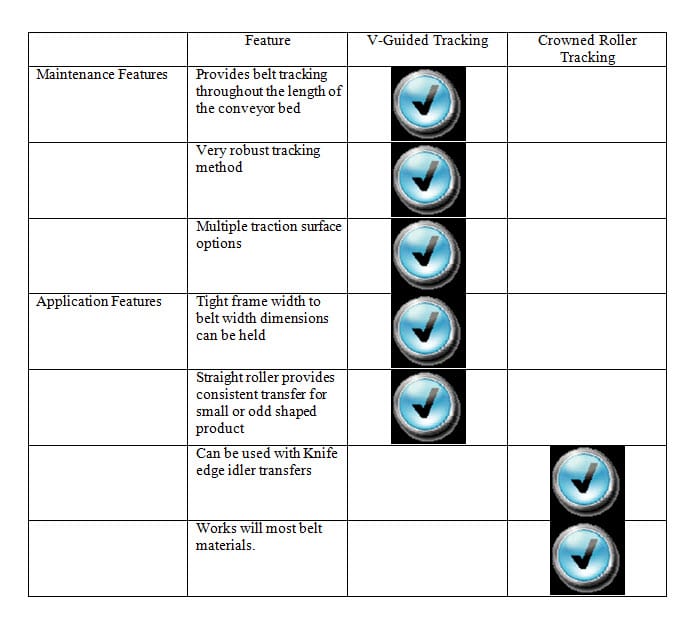

When the flat belt on such a pulley is off-center and the pulley rotating the belt quickly moves up to the largest radius at the top of the crown and stays there. The 2 most common methods used to aid in the belt tracking are crowned roller and V -guided belting. These shapes generate sufficient steering forces to guide a belt.

440C stainless steel rollers offer better corrosion resistance than chrome-plated steel rollers. Crowned rollers have a slight curve which is invisible to the naked eye to stay centered on surfaces that are not perfectly aligned andor not perfectly flat. Each CAD and any associated text.

A crowned pulley eliminates the need for pulley flanges and. The crossed-roller bearing design is the roller equivalent of the x-type ball bearing design. This study proposes an improved design method for roller guide.

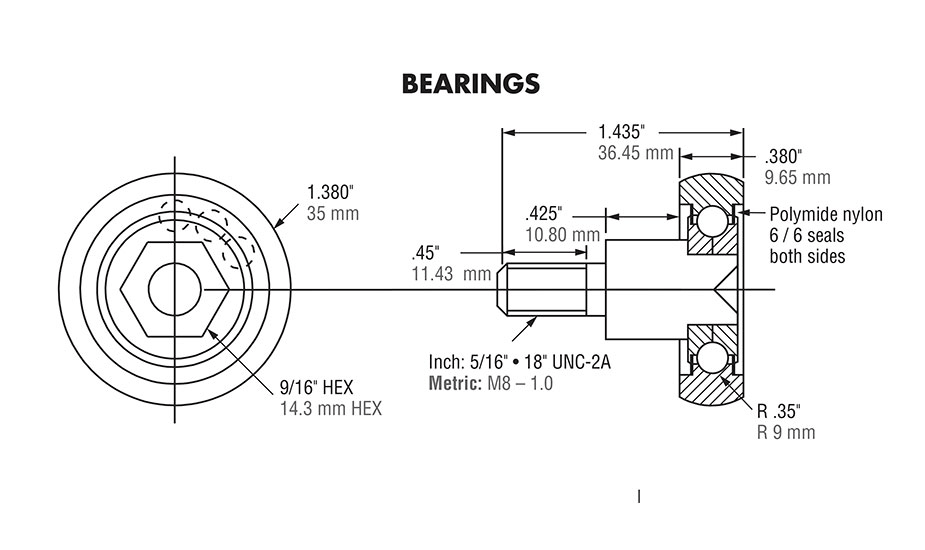

For technical drawings and 3-D models click on a part number. The long fatigue life is the one of the most important criterion for the design of rolling bearings however due to complex and diverse internal geometries each type of rolling bearings require a different design formulation. 4 Downloads 0 Likes 0 Comments.

The crown is important to keep the belt tracking stable preventing the belt from walking off the edge of the pulley. The latest computerized grinding machines along with the basic beam principle roller specifications and the users operating load requirements are the factors leading to precision crowned rollers.

Crowned Pulleys Which Option Is Right For You Sparks Belting

Belt Conveyor Tracking V Guided Vs Crowned Roller Dorner Conveyors

How Crowned Pulleys Keep A Flat Belt Tracking

Belt Conveyor Tracking V Guided Vs Crowned Roller Dorner Conveyors

Crowning Benefits Paper Film Foil Converter

Belt Conveyor Tracking V Guided Vs Crowned Roller Dorner Conveyors

0 comments

Post a Comment